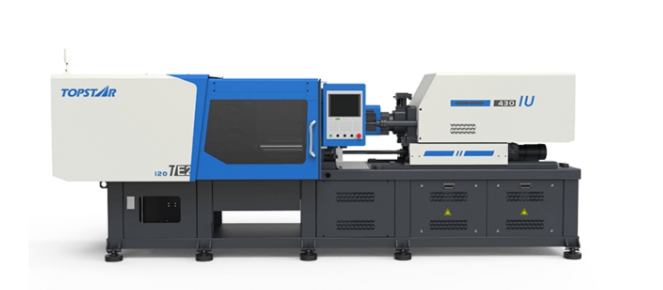

Injection molding machines are the equipment responsible for producing many plastic products we use daily. These machines are usually expensive, leaving our potential buyers wondering why they are so expensive. Therefore, as a professional injection molding machine manufacturing company, we will explain in this guide the various factors that make injection molding machines an essential choice so that users and consumers can have a deeper understanding of their value and the technology behind them.

Advanced Technology and Precision Engineering of Injection Molding Machine

One of the main reasons why injection molding machines are expensive is that they use self-developed or certain advanced technologies and precision engineering in their design and manufacturing. These technologies precisely execute every aspect of the injection molding process. In addition, innovative technologies such as servo motors and digital controls have improved the efficiency and accuracy of these machines, further pushing up their costs. In addition, the precision engineering involved in the entire manufacturing process also increases their costs. Some of the high-quality materials used ensure the machine components’ durability and lifespan.

High-quality materials and components in injection molding machine

Depending on the product, these machines need to withstand the harsh conditions of the molding process, including high temperatures, high pressures, and mechanical stresses. Therefore, manufacturers use high-quality materials. Key components such as the injection, clamping, and mold base are usually made of high-grade steel or special alloys. These materials are chosen for their ability to maintain structural integrity and performance after long-term use. In addition, integrating advanced electronic and hydraulic systems further increases costs. High-quality sensors, actuators, and control systems are essential to ensure that the machine operates accurately and reliably.

R&D Costs

The amount of money manufacturers spend on research and development (R&D) also influences the high price of injection molding machines. Developing new and improved injection molding technologies requires much R&D work, including experimentation, testing, and design improvements. This involves exploring new materials, developing innovative molding techniques, and improving the performance and efficiency of the machine to remain competitive and meet changing market demands. The final price of the injection molding machine reflects this.

In addition, the constant pursuit of innovation has led to advanced features in many modern injection molding machines, all requiring a significant R&D investment. Adding these advanced features increases the complexity and price of the machine.

After-sales support and maintenance

Providing after-sales support and maintenance services is another factor contributing to the high price of injection molding machines. These machines are complex and require regular maintenance and technical support. General after-sales support includes installation, commissioning, troubleshooting, and technical assistance. Skilled technicians and engineers can solve various problems and provide solutions to ensure the machine’s smooth operation. Maintaining a robust after-sales support network is costly and affects the overall price of the injection molding machine. Manufacturers factor the costs associated with these maintenance contracts and service agreements, including labor, parts, and logistics, into the price of the injection molding machine.

Economy and market demand

Overall economic conditions and market demand also affect the price of injection molding machines. The injection molding machine market is relatively niche and specialized, and demand is mainly driven by industries such as automotive, electronics, medical devices, and consumer goods. The limited market size and the high customization required for different applications result in lower production volumes than mass-produced consumer goods. This limits manufacturers’ ability to achieve economies of scale, resulting in higher machine costs.

Value of Injection Molding Machines

The high price of injection molding machines is due to various factors, including advanced technology and precision engineering, high-quality materials and components, research and development, after-sales support, and more. Each of these factors contributes to the overall value and performance of the machines, ensuring they meet the demanding requirements of modern manufacturing. These machines’ advanced technology, precision, and reliability justify their price, enabling them to achieve efficient, consistent, and high-quality production.