If fossil-fuel powered vehicles are to be removed in the next few years, technology must advance, and not slowly. It must run (or drive!), not walk.

Several car companies have already started manufacturing their own electric cars today; Tesla – as we all know – is the industry pioneer, but the general goal is to transition out of all new gasoline and diesel vehicles by the year 2035. The EU Parliament has in fact approved the ban on new fossil-fuel cars from 2035.

The Unbelievable ban on fossil-fuel cars

In June 2022, the EU assembly decided in Strasbourg, France, to force automakers to cut carbon dioxide emissions by 100 percent by the middle of next decade. Additionally, EU legislators pushed towards a 55 percent decrease in CO2 emissions from cars in 2030 compared to 2021. Great news for the environment, not so great for your bank balance if you’re planning on buying a new petrol or diesel car in the next 10 years.

In today’s market, electric mobility is (forcedly) growing popular. The future of transportation has already been identified as electric vehicles. They are expanding and are estimated to overtake the auto industry in a few years.

This is however beneficial: through technological innovation, e-Mobility is the answer to today’s issues about climate change, dependence on fossil fuels, and a significant step towards environmental protection.

Vacuum technology’s crucial role in the process

Technical innovation is a must for new e-mobility advancements and vacuum technology is a big player in various processes.

It started as an old-school industry innovation with car motors over 60 years ago and has been used ever since. Given that it is currently playing a significant part in the most recent e-mobility innovation, it will be used for many years to come.

Mobility and vacuum technology: a persistent, triumphant interest

Vacuum technology has been used for more than 60 years to support the development and manufacturing of traditional engines and batteries, therefore it is not a fresh breakthrough in the field of mobility.

The Agilent case

Agilent is a manufacturer of vacuum systems, accessories, and equipment.

Because of its roots in the field of vacuum technology, Agilent is also not a new player in the e-mobility industry. Agilent helps manufacturers across the world in both the core steps of creating renewable battery technology and the supplementary procedures, namely vacuum and leak detection tests. They are actively participating in cutting-edge industrial processes for sustainable mobility and car electrification. To find out more about Agilent and vacuum technology, go to https://www.agilent.com/en/product/vacuum-technologies .

Which e-mobility processes have benefited most from vacuum technology?

Vacuum is already used in a variety of phases and procedures connected to electric mobility. It will be interesting to see if vacuum technology can grow as the market for electric vehicles develops. With vacuum technology, the production of electric vehicles will become lighter, more cost-effective, and more efficient.

Although vacuum technology for use in electric vehicles is still in its youth, the potential impact is already obvious. A cleaner, greener future for all of us.

The electrolyte-filling phase of a lithium-ion battery is only one of the numerous phases and procedures where vacuum is fundamental. Future trends for vacuum in automobiles include the use of vacuum in fuel cells, in addition to lithium-ion batteries. Let’s dive deep in the stages where vacuum is the dominant player.

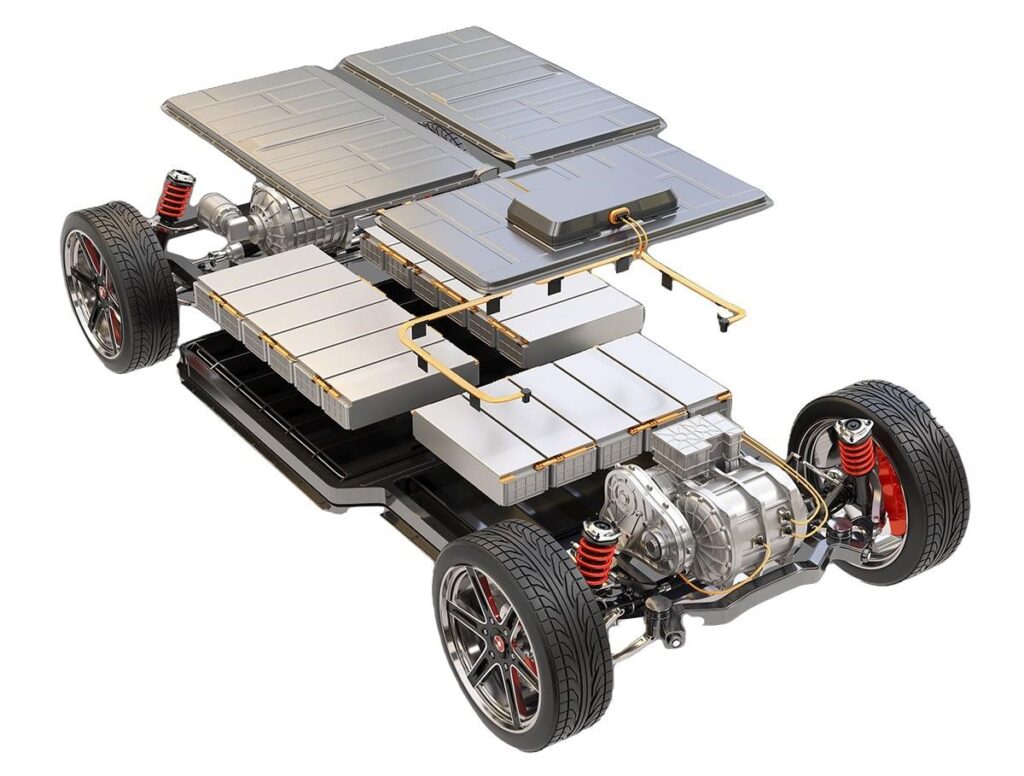

1. Battery production

More than half of the battery manufacturing process uses vacuum technology. Agilent has been assisting lithium-ion battery manufacturers with their production, quality control, and safety measuring processes. Agilent’s vacuum technology now makes up more than half of the steps in making batteries as a result of this.

2. Battery Cooling

Car manufacturers are now under pressure to create new heat management technologies, as batteries are becoming more effective and powerful. Battery temperatures must be kept between 20 and 40 degrees Celsius via cooling systems. The most effective method for maintaining the battery pack at the right temperature range has been demonstrated to be liquid coolers; nevertheless, the largest drawback is the possibility of a leak or spill. Battery durability and battery pack safety can be both seriously affected by water leaking in battery coolers, which is a serious issue. The cell needs to be totally leak-proof in order to guarantee a long battery life. A leak test is carried out using a vacuum leak detection apparatus, which may find even the smallest leak using a helium leak detector, to ensure leak-proofness.

3. (HVAC) Systems for Heating, Ventilation, and Air Conditioning

High-performance electric motors produce far less heat than thermal engines do. Therefore, how do electric cars manage their cabin heating? They use – you guessed it – electricity. To generate interior heat, they usually use one or more resistive heating elements. Early electric cars actually used simple resistive heaters, whereas modern cars use heat pump systems to move thermal energy from the outside to the inside. For these modern HVAC systems to produce sturdy and durable components capable of successfully absorbing and directing heat, extensive vacuum and leak detection technologies are required.

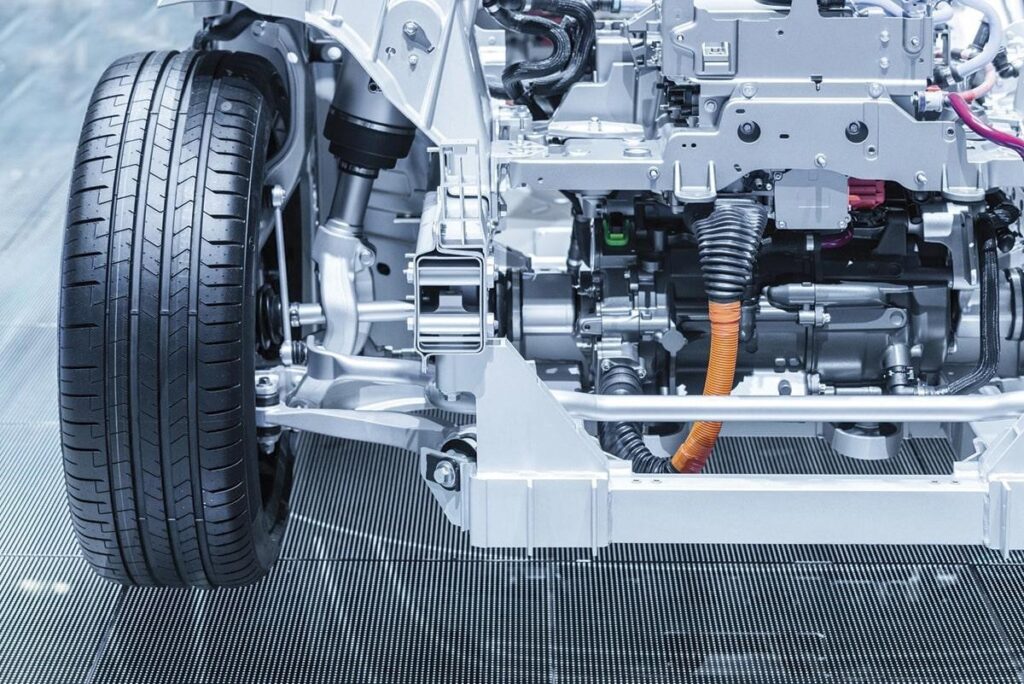

4. Electric motor and leak detectors

Manufacturers of electric vehicles are investigating new motor/generator technology to make them more efficient, lighter, quieter, and even cheaper than conventional electric motors. Because water is the number one enemy of electric and electronic components, Agilent helium leak detectors are enabling faster and more precise leak detection and monitoring for completely sealed electric vehicle motors.

5. Electric & electronic components

To increase the effectiveness of an electric vehicle’s internal electrical distribution, new materials and techniques are constantly being used. This includes dealing with issues involving higher voltage, heat, and insulation. Inverters, connectors, filters, busbars, and safety devices all have crucial functions in propulsion-grade power electronics. All of these components need an insulating layer or environmental coatings. Agilent provides turbopumps and turbomolecular pumps for this cutting-edge coating technology. To find the most recent turbopumps and turbomolecular pumps, visit the Agilent website.

6. The latest fuel cell for e-mobility

Fuel cells use hydrogen gas to produce electricity through a chemical reaction, with the byproducts of just water and heat. In fuel cells, hydrogen electrochemically reacts to produce energy that powers the vehicle. Additionally, brake energy is absorbed and stored in a battery to provide additional power during brief acceleration episodes. Generators for fuel cell technology, gas tanks, and distribution lines must be hermetically sealed to prevent leaks that could compromise performance and safety.

Future Trends for Vacuum Technology in Vehicles

Vacuum technology has been used in the automotive industry for more than a century and shows no signs of slowing down. It still has a lot of potential in the field of electric vehicles and will be a key player in the future of e-mobility.

Public concern about climate change is only growing, which in turn steps up government efforts to reduce carbon emissions. By 2040, more than half of all new and sold passenger cars will be electric, predicts Bloomberg New Energy Finance.

Agilent is dedicated to assisting this shift by offering the best, most advanced, and effective vacuum technology machines and equipment. Vacuum technology will undoubtedly play a significant role in the automotive industry in the future, particularly with regard to electric vehicles.